Copper, bronze and silver. Polished and ready to string.

Good thing it’s supposed to rain tomorrow. The 15th is also my deadline for the June “Cranberry Report.” A morning of writing, an afternoon of polishing, and an evening of stringing necklaces and putting earrings together. Busy day.

Filed under Uncategorized

Copper clay pieces after firing, brass brushed. The round pieces are hollow forms, not solid.

PMC3 smeared into recessed areas. 2 pieces are sanded down to show the copper surface.

Finished earrings. PMC3 has been torch fired. Some shrinkage. Have not yet tried filling the cracks and refiring. Maybe I don’t mind the slight openings between some of the silver and copper. It would be good to know what happens if I were to fill in and refire….

Soldering sterling silver posts on copper clay. Hmmmm…. The one on the left worked well the first time. The one on the right took three tries and a lot of solder. Soldering on copper clay feels very similar to soldering on PMC original. The fired clay is still quite porous. I tried burnishing the area where I was going to put the post. Still tricky soldering. Has anyone else had trouble with this?

The hole that is distant from the post is a vent hole in the hollow form. The hole right next to the post is where the copper started to pit when I tried to solder.

Filed under Uncategorized

My first attempt at firing combined bronze and copper clays. Photo shows placement of the pieces in the first layer of charcoal. The copper/bronze combined pieces are at the top. I placed more charcoal on top with a second layer of copper and bronze beads. Placed another inch of charcoal on that and fired the first phase with the lid off. Those are 20 gauge bronze wire loops in the larger pieces.

In my enthusiasm to find out how the combined pieces would fire, I took the container out after the first stage of firing, let it cool, then put it back in the kiln to ramp up to 1550ºf and hold for three hours. After the first hour, I remembered that I had not filled the container to the top with charcoal, nor placed the lid on, as I have done with other firings. Yikes! I opened the kiln and while everything was glowing orange, I pulled the pan out with a kiln fork, placed it carefully on the concrete floor, filled the container with charcoal, (on top of the glowing orange charcoal in the pan) and placed the lid on and put it all back in the kiln and shut the door. The kiln went back up to temperature and continued to fire for two more hours. I was pretty nervous when I took the pieces out. I was sure they would have melted or something from the first hour at 1550º without any extra charcoal or the lid. They turned out fine. No bad surprises.

Three pieces have been brushed slightly with a brass brush. The piece in the upper right has been buffed with Fabulustre on a wheel. The contrast gets lost. Even more so in bright light with a shiny piece. Baldwin’s Patina is recommended to darken the copper for more of a contrast between the copper and bronze when it is polished. I noticed that Rio Grande carries it.

I have not had much experience with torch firing silver PMC, but I really like the contrast I’ve seen between copper and silver, or bronze and silver in the pieces on Hadar’s blog. I tried some test pieces of each by filling the recessed lines with PMC3, letting them dry on a cup warmer, then sanding them until the silver clay surface was smooth and even with the fired base metal clay pieces. I used a butane torch to heat the PMC3 to a dull red glow, kept the flame moving and held the color for 2 minutes and then quenched the piece in water. The results look a little rough, but it worked. If I were making pieces to sell, I might try filling in some of the spots and lines with more PMC, and refire it with the torch to get a more even inlay.

(I knew there was a reason to save these bronze beads that came apart. They made good test pieces.)

Filed under Uncategorized

Today was the 5th time I’ve fired copper and bronze clay. All rocks beads in this batch, and all seemed to have fired well. The clay is Hadar Jacobson’s bronze and copper clay powder, and I fired using the directions from her blog. The combination of two metals in the same load did not have any effect on each other. Its easy to tell the bronze and copper clay from each other in the pre-fired beads.

After firing, they almost look the same. But the bronze clay shows some of the patina from firing. This will polish away when I buff the beads. I will try to recreate it by applying heat with the torch, after the bronze is polished.

It was a good rainy day, so it was easy to stay put in the studio to finish a second batch of copper and bronze to fire in the kiln tomorrow.

Filed under Uncategorized

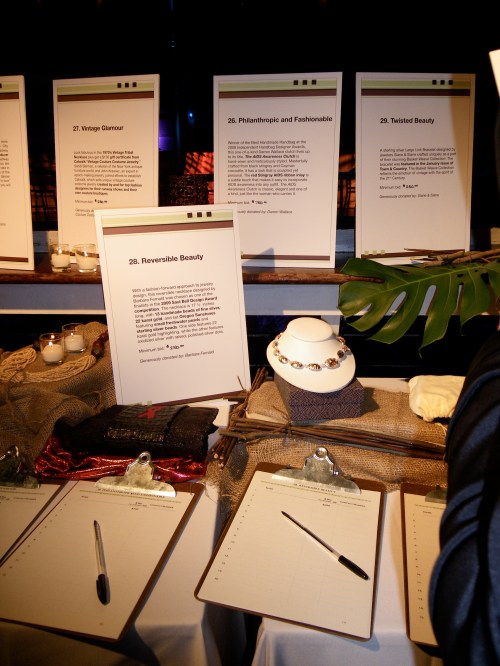

The Tuesday night party to celebrate Ubuntu’s 10 years of commitment to the children of South Africa was an incredible event at Terminal 5 in New York City. Many Islesford friends were there as well as many of the staff from the Ubuntu Education Fund office in Port Elizabeth, South Africa. 500 people generously helped to raise over $1 million for this incredibly worthy cause. The music of Paul Simon and Hugh Masekela had everyone out of their seats and dancing. Congratulations to Jacob Lief and Banks Guaxula for establishing the Ubuntu Education Fund which has provided lifesaving HIV support services and essential education resources to more than 40,000 vulnerable children and their families in Port Elizabeth, South Africa.

It was a privilege to attend the Gala and to be able to contribute a piece of jewelry to the silent auction.

I believe the final bid was $950. Yee Ha!

Filed under Uncategorized

First foray into copper clay. It feels a little more “rubbery” than the bronze clay. I finally understand about how these clays shrink while drying, even before they are fired. On the square beads, I made the sides first, let them dry, then used copper clay paste to attach the wet top and bottom. As they dried, the tops cracked. Only one bead dried without cracking. Next time I will attach dry tops to dry sides.

Copper clay beads before firing.

The beads were not shiny or metallic looking after they were fired. But they polished up well with Fabulustre and the buffing wheel. I really like the color, and can’t wait to try more with both the bronze and copper clays. But first, off to New York for two days!

Copper beads after firing. Unpolished and polished.

Filed under Uncategorized

Bronze clay pieces before going into the kiln:

Below, the ones that didn’t work. They looked okay except the sides shrank more than the top and bottom. I used the powdered clay for the tops and the Rio Grande clay for the sides. Why was I surprised ?

On closer inspection, the tops and sides and bottoms did not bond at all. Sides sintered properly, (hard to break apart) but other pieces were brittle. Frustrating, but not yet discouraging. I will not try mixing the two types of clay again.

On closer inspection, the tops and sides and bottoms did not bond at all. Sides sintered properly, (hard to break apart) but other pieces were brittle. Frustrating, but not yet discouraging. I will not try mixing the two types of clay again.

The little “stone” bead made from the powdered bronze clay worked out as I had hoped it would. So did the flat beads made from the Rio “Bronzclay.” The experiment to fire them with wax wire in place worked out well. The wax melted away when the clay was firing, but the holes stayed open. Most of the beads were fired in an upright position so the wax could drain straight down. But a few were fired laying flat in the charcoal and the wax still drained and burned away.

Everything polished really nicely with a buffing wheel and Fabulustre compound. Even the pieces that I didn’t think fired properly.

Filed under Uncategorized

I am firing the second batch of bronze clay beads that I made yesterday. When I get frustrated at how long the firing process is, (1 hour 20 minutes, cool down, then 3 hours more) I think about the first incarnation of Precious Metal Clay that I tried in 1997. That took about 3 hours to fire, too. Now when I use PMC +, I can fire in less than an hour. It has spoiled me for the bronze.

With this batch of beads, I used up the rest of my 200 gram package of Bronzclay from Rio Grande. I was not impressed with the texture of the clay and what a mess it was, but was determined to find a way to make bronze clay work for me. Then I tried Hadar Jacobson’s Bronze Clay powder. I followed the directions on her blog (see link at right) and the clay was a dream to work with! What a difference. Now I just have to wait to see how the pieces come out. I will definitely buy the powdered clay again before I buy the package. I can’t wait to try the copper clay powder tomorrow to see if it has the same feel. If you are a metal clay person, and you have not yet seen Hadar’s blog or web site, do it now. I guarantee you will be inspired by her creativity and her generosity in sharing her experience with these new forms of metal clay. You can also buy bronze and copper clay powder from her site.

Filed under Uncategorized